For a perfect sanding result

Electric tools and abrasives by MENZER

Sanding machines

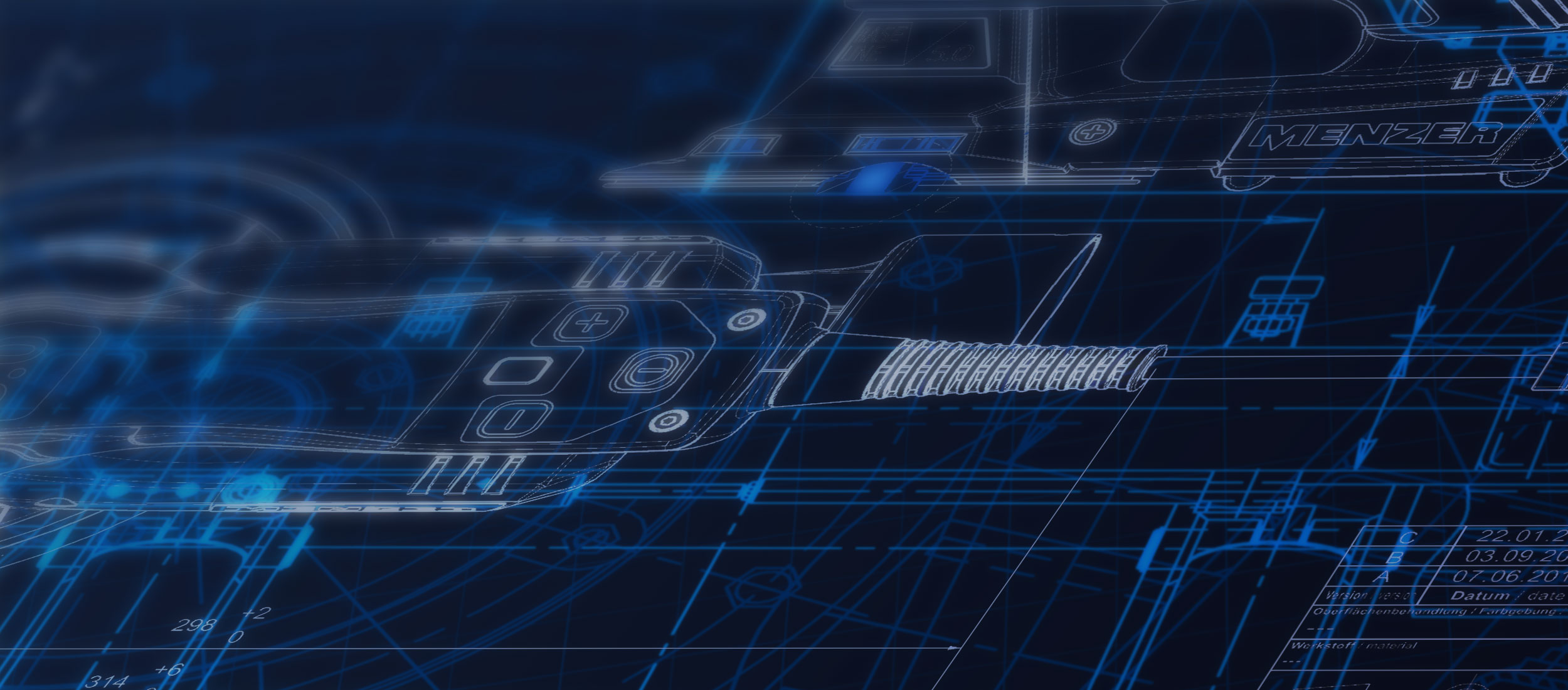

Longneck sanders

The MENZER longneck sanders are the perfect choice for any drywall construction project. Many practical and innovative details like a direct drive system, a telescopic extension system, an integrated dust extraction unit or the extremely powerful motors allow comfortable and uninterrupted sanding.

Random orbital sanders

The random orbital sanders by MENZER offer solidity, sturdiness, perfect ergonomics and extremely low maintenance operation.

Compact Drywall Sanders

The compact and lightweight design of MENZER's compact drywall sanders makes it an all-rounder for interior work tasks.

Industrial vacuum cleaners

Industrial vacuum cleaners

MENZER is a one-stop shop for sanding technology and develops high-quality industrial vacuum cleaners that offer an excellent basis for dust-free and healthy work conditions when combined with MENZER sanders. The machine can, of course, also be used as a standalone industrial vacuum cleaner.

Minimizing dust

Minimzing dust during all sanding processes promotes a healthy work environment. But only the right combination of sanding machine, abrasive und vacuum cleaner enables almost dust-free sanding.

Abrasives

Sustainable solutions – FSC-certified packaging and abrasives

With FSC certification for paper-backed abrasives, we ensure that these products originate from responsibly managed forests and actively contribute to protecting our environment. Thank you for your trust in our sustainable products!

MENZER als Arbeitgeber

MENZER als Arbeitgeber

Seit 2006 entwickeln und vertreiben wir an unseren Standorten

Markranstädt und Leipzig hochwertige Schleifmaschinen, Industriesauger und Schleifmittel. Darin steckt unser Herzblut.

Deswegen suchen wir stets Mitarbeiter, die motiviert und engagiert

sind. Wir lieben unsere Arbeit und unterstützen unsere Mitarbeiter,

weil wir sie schätzen.

MENZER ist für Sie da

MENZER ist für Sie da

Tel.: +49 (0) 34205 9 27 94 00

Servicezeiten: Mo. bis Do. 8 – 17 Uhr, Fr. 8 – 15 Uhr